Afternoon all.

Following up from my earlier threads, I thought I'd give some detail on my project and what I have learned about willow and home-made clefts.

1) You need big treesMy tree was too small to be useful for our purpose. It has been very interesting as a learning experience, but in this game, size really does matter. My tree was approximately 35 inches in circumference which meant that however hard I tried, I could not make the correct cuts or avoid the real heart of the tree. If anyone is interested in more detail on this I would be happy to explain but simply put, the clefts from small trees will never make good cricket bats. The compromises you have to make to get the cleft size you need, leads to clefts which split, bend and warp uncontrollably. Try to find trees that are at least 52 inches around.

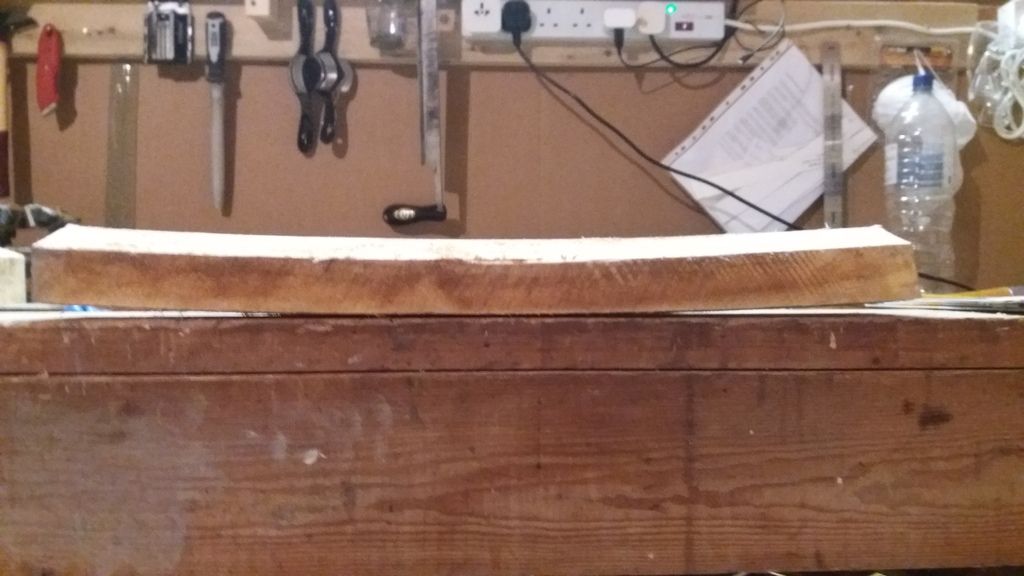

2) Cut your clefts as thick as possibleThin clefts warp more than thick clefts do. See the images below, demonstrating the difference between 2 clefts, and showing what happens when a cleft is cut too thin. Admittedly, this is partly due to my tree again, but as a rule of thumb for the future, I will always cut bigger if the wood is there.

3) Cut your clefts as wide as possible

3) Cut your clefts as wide as possibleAnnoyingly, it turns out that as it dries, wood will go in all kinds of directions. The cleft pictured below seems to be thick enough, and has dried flat. But, it has bent like a banana side to side. Again, my advice is that for bat clefts, 'more is more'. They need to be cut big, and as accurately as possible.

4) Candle wax is a pretty effective sealer

4) Candle wax is a pretty effective sealerI literally melted down a big handful of tealights (available from B&Q etc), to use as the sealer for the ends of the clefts. The wood from the very top of the tree was always going to split due to the tightness of the rings, but the clefts from the bottom of the tree have not split at all. They have dried successfully and I am happy that double dipping in the candlewax is 'good enough' for this purpose. Of course, it's not the professional solution used by the big suppliers, I understand that they have special wax that is made for purpose.

5) My garage is a decent environment for seasoningIt's not perfect, but the garage is definitely effective as a place to dry clefts. My first 4 clefts have lost an average of 1lb 10oz each, in about 10 weeks - approx 25-30% of their original starting weight. I don't have any guidelines on this, it's likely that drying this quickly is not the optimum, but anyway, it does work. In future, I may try keeping clefts outside under a tarp as well, to see how the drying rates compare.

6) Seasoning timesThis is a work in progress, but after 10 weeks in the garage the clefts can be planed comfortably. I tried planing the freshly cut clefts back in June and it was pretty much impossible, so this is at least an indication of seasoning requirements. Probably by October the wood will be easy to work.

7) Lead shotI have learned the hard way that it is best to avoid taking trees from pheasant shooting areas! The lead shot becomes embedded within the tree trunk, and you only notice it when you plane off the top half. This is not beneficial to your equipment.

Overall, I've learned that with a little time and effort, this is definitely do-able. The main issue is finding a big enough tree belonging to a friendly enough farmer. Hopefully I will be able to get a better tree and improved results later this year.

Author

Topic: Thoughts on home-made clefts (Read 2635 times)

Author

Topic: Thoughts on home-made clefts (Read 2635 times)