Flamboyance can have consequences...

It's mid March and the weather seems to be getting warmer, or I'm getting used to the cold, and winter nets is now very much underway. The first net is always an eye opener. A winter of listening to the BBC's splendid Test Match commentary gives you delusions of grandeur. You stride into the nets with the confident swagger of Viv Richards, take guard with the poise and precision of Jonathan Trott, and stare the bowler down... he knows what's coming, an onslaught!

The bowler runs in... you lift your bat... the ball is released... THEN?

You don't move your feet, you miss the ball by a considerable margin and you're only explanation for what's happened is that it must have moved square, swung a mile and the pitch is making the ball do all sorts of ungentlemanly things.

The reality is that my cover drive doesn't look like Kumar Sangakarra's, I don't pull like Ricky Ponting and I have no idea how Viv Richards used to walk across his stumps and smash it over mid wicket. My philosophy is that "a leave is a wasted opportunity to score".

Despite this, we all want to play some outrageous shots in the nets. We now have an example of one of those flamboyant strokes that if pulled of makes us look dismissive and arrogant. Conversely, it can make us look like a fool.

This bat has, in part, succumbed to one of those shots.

A slightly mis timed flick of the ball had smashed into the back of the edge. Now unfortunately, Willow is a naturally soft timber and the only reason it stands up to the punishment of a cricket ball is because it's pressed using one of these...

They look a little bit more modern nowadays, but essentially they serve the same purpose

This machine compresses the fibres of the face and edges but doesn't make much difference to where this ball hit.

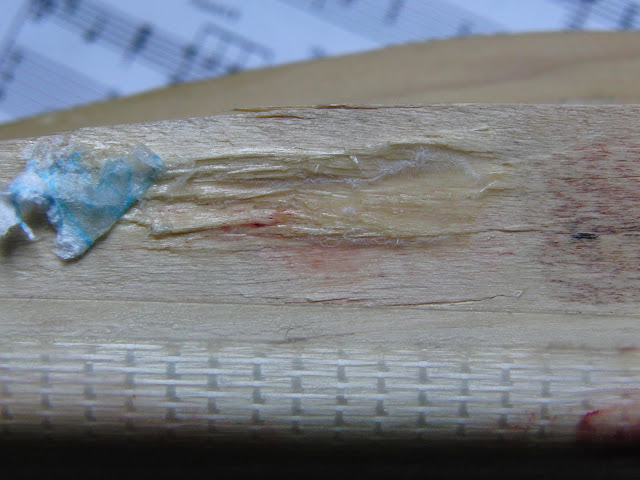

Please bare in mind that I forgot to take a photograph before I repaired it. All the wood that's glued down in the first two photos was blown out the back. The fibres had been crushed together quite badly and it became apparent the repair was essentially going to be cosmetic. I picked out as much wood as I could to allow the glue to have something to stick to, in the end it looks considerably better than when it came to me.

The splits show where the wood was poking out the back

Glue and sandpaper are your best friends

GONE!

Whilst the chosen shot was no doubt the main reason this happened, undeniably a factor that contributed was the rock hard bat breaker of a cricket ball. Every club has someone who turns up with a new ball at nets, sometimes it's a good quality ball that will age beautifully and last a season if cared for. The other type of new ball you see are up there with Diamond on the Mohs Scale, they have been dipped in lacquer and baked in the oven at 4000ºC!!!

I don't begrudge anyone bowling with a shiny new ball, after all no one likes bowling with the tatty sponge that floats around at the bottom of the bag of practice balls. I do dislike someone hurling a 5.5 ounce concrete sphere at my pride and joy. No! Not that pride and joy... the one in my hands... No wait, that came out wrong... you know what I mean.

To those of you who own these "bat breakers", bat makers around the world want to tell you off. Or give you a better ball, actually we'll do that instead cause we can be guaranteed they'll be destroyed, never to be unleashed at someone else's pride and joy.

Author

Topic: Beach's Bat Making (Read 33174 times)

Author

Topic: Beach's Bat Making (Read 33174 times)

Author

Topic: Beach's Bat Making (Read 33174 times)

Author

Topic: Beach's Bat Making (Read 33174 times)