Okay, a little bit of clickbait here, as it's not something new - a fair few companies such as B3 and Kelsall have done this. Having seen a fair few Indian bats have very thin oval handles, and me being one who avoids double gripping if possible, I've decided to double bind 2 of my SS cricket bats. Two reasons for this: The handle was extremely thin and I feel that a second round of binding will probably help with the durability of the thin handle/prevent the handle from delaminating too soon/aggressively, hence increasing the lifespan of the shoulders and the bat.

Lovely example of a butterfly low grade bat: (As a side note, Laver sell Butterfly Gold grades for like $800... Saw one on facebook on auction and nearly spat out my coffee when they mentioned the RRP. Looked lovely, and I understand the premium product thing, but it is butterfly... Eventually went for $580 USD - that's £450 ish)

The Laver Butterfly. (Absolutely gorgeous, and I'd probably have been allured for £300 ish... I've really gone off topic, but this has genuinely got to be one of the most beautiful butterflies, but also frustrating that it's been priced so high... This should probably be discussion for another thread!)

As you can see in the following pictures, the shoulders are reasonable sized, but aren't exactly the thickest. The handle feels like what I'd expect a size 6 to have in terms of girth.

So at the start of the process, I decided to weigh the bat, and it came in on the scales at 2lb 7.32oz ungripped. I started off by gluing the binding - all of it as I found that the binding from the factory felt a bit to fabric-ey, suggesting that it hadn't been glued post bind.

As a fan of more oval handles, I decided to put on some tennis overgrip tape just to pad out the handle slightly. It makes it very ever so slightly oval, the difference is a little noticeable, but almost negligible. I decided to do this before binding:

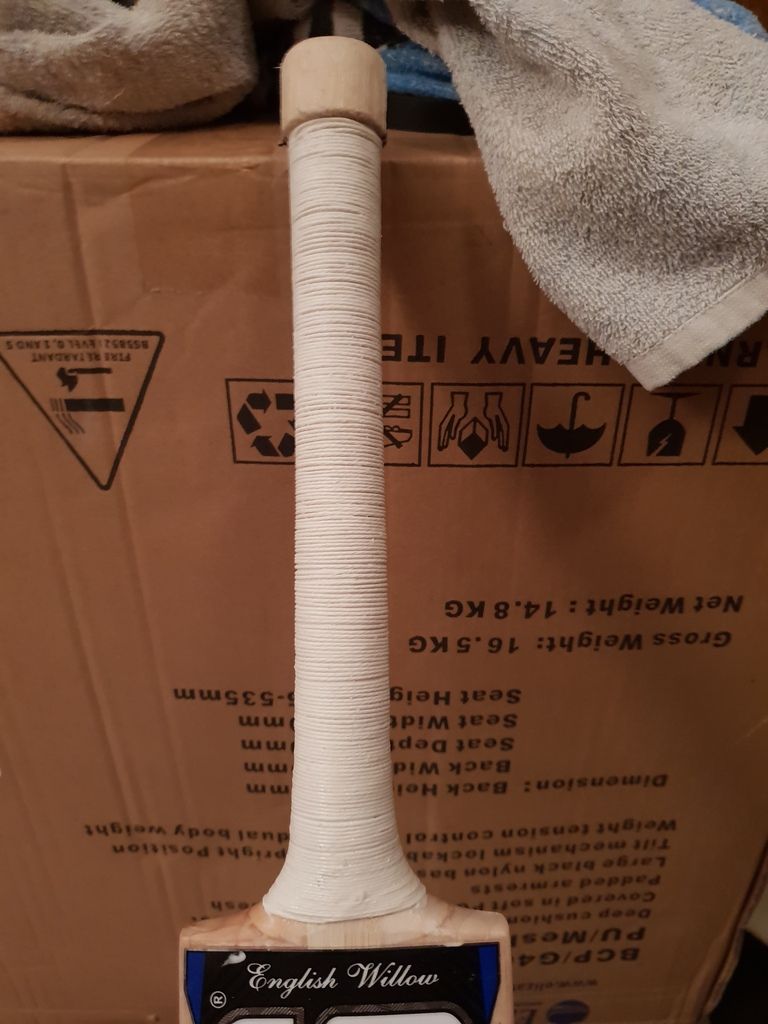

To start off the binding, I had about an inch of binding at the top which was parallel to the handle, which I then overlapped with binding. This is to ensure that the twine at the top of the handle doesn't come loose. I spread some glue along about a 1.5 inch length of handle and then started binding. I pretty much rinsed and repeated this till the end.

And a few pics of the ending of the binding (Actually messed up and had to unravel a bit, but just to demonstrate what you are trying to do to get the twine to end underneath the binding) What I learned was that the loop can get stuck under the binding IF you either have too much binding, or you glued the handle prior to the end part. What I would recommend is leaving about 2cm before the loop, and don't glue the handle underneath as you're wrapping round then pulling through. Only glue the binding after you've finished pulling the loop through and tightened the twine, and then cut off the excess twine once the glue has set a bit. If I wasn't so slow at binding by hand, this issue would probably not happen!

Aaaand the end weight? 2lb 8.31oz. This is a 1oz increase, but I suspect would have been around 0.7-0.8oz without the overgrip and insulating tape.

The gripped weight was 2lb 9.9oz, and it felt much better in the hands, especially without the sudden dip in the middle of the handle thanks to the overgrip tape. This might seem like a pointless thread, but I wanted to see if any batmakers agree with me here regarding the benefits of a second layer of binding. It allows for almost like a double gripped feel, except with what I reckon would be extra sturdiness of the handle and also around 0.8oz less weight. Also, if you find that the binding ends quite high up the handle, you can rectify this by binding even further down, which I did for around 3-4 rounds, as I didn't feel it was massively high up.

Oh, and in terms of time taken, it was done entirely by hand and took me 45 minutes, so quite a lengthy process, but the end result was satisfying. Hope this wasn't too boring, and provides some sort of platform about discussion regarding handles. They're probably one of the 3 most important parts of a bat, with the other 2 being pressing and shaping/balancing. Without a good quality handle/join, you won't get the best out of a piece of willow in terms of longevity and performance - the reason why I'm hesitant at times with bats from Asia as they can come with filler and super thin handles.

Author

Topic: New way to deal with thin handles??? (Read 3935 times)

Author

Topic: New way to deal with thin handles??? (Read 3935 times)